In 1906, German chemist Alfred Wilm (1869-1937) discovered that the hardness of aluminum could be significantly increased by adding a small amount of copper. This discovery prompted the creation of "duralumin" (also known as "hard aluminum"). The tensile strength of duralumin is usually between 300 and 500 MPa, and its high stiffness and hardness make it widely used in aerospace and other fields.

The strength and hardness of aluminum alloys are improved mainly because different alloying elements such as copper, manganese and magnesium enhance the matrix strength of aluminum through solid solution strengthening. Other elements such as titanium, vanadium and boron improve performance by refining grains and increasing nucleation, while cadmium and scandium mainly improve performance through second phase strengthening. The different combinations and matching of these alloying elements make aluminum alloys have a wide range of applications and different performances.

A2017 is called a hard aluminum alloy, A2024 is called a super-hard aluminum alloy, and A7075 is called a super-hard aluminum alloy. 7075 aluminum plate is also called 3.4365 aluminum. 2017 aluminum contains copper and magnesium, and has excellent strength. It has the same high strength as steel materials and can be used for aircraft parts, etc.

Although they belong to the same 2000 series, 2024 t351 aluminum has higher copper and magnesium content than A2017, and its strength and machinability are better. However, A2024 has slightly worse corrosion resistance than A2017. A7075 mainly contains magnesium, zinc, and copper, and has higher strength than A2017 and A2024. On the other hand, it may have stress corrosion cracking.

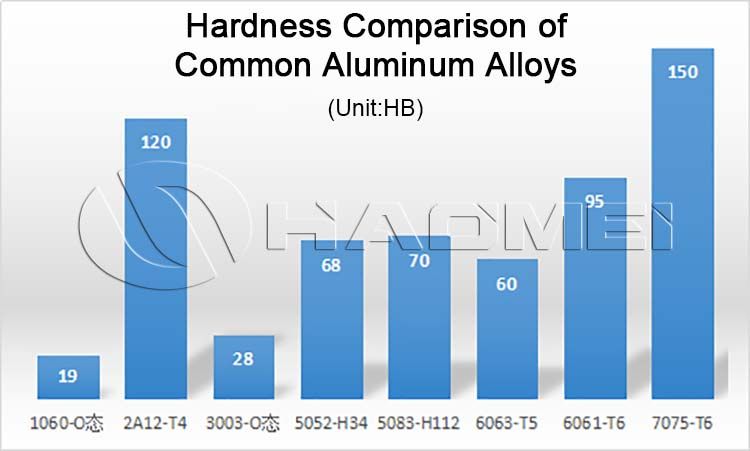

First of all, hardness is directly related to the chemical composition of the alloy. Secondly, different states also have a great influence. From the perspective of the highest hardness that can be achieved, 7>2>6>5>3>1 decreases in order. A7075 is one of the strongest aluminum alloys, and its strength is comparable to that of iron-based metal.

5052 aluminum alloy belongs to the 5000 series of aluminum alloys and contains magnesium. It is the most common aluminum alloy and is also called general-purpose aluminum. It is used to manufacture various machinery, ship and automobile parts, etc. The characteristics of A5052 are light weight and good processability. However, the strength is not too high. On the other hand, the strength of hard aluminum alloys can be improved by adding copper. A7075 is the strongest aluminum alloy not only compared to A5052, but also among all hard aluminum alloys.

A5052 is a general-purpose aluminum material that can be used as a material for various parts. 3.4365 aluminum is characterized by its high strength and can be used as a material for parts that bear loads or impact loads. However, A7075 has poor corrosion resistance and requires full attention to the use environment.

Original Source:https://www.aircraftaluminium.com/a/what-are-duralumin-alloys.html

Tags: 7075 aluminum plate ,

Contact Us