Aluminum alloys are mainly used as structural materials on aircraft, such as skins, frames, propellers, fuel tanks, wall panels and landing gear struts. Aluminum alloys for aerospace manufacturing are important structural materials at present. Some new thick aircraft aluminum plates like 7075-T7651 have been developed.

7075 aircraft aluminum sheet is one of the commercially available strong alloys. It is a high-strength, heat-treatable deformed alloy developed by Alcoa Company in 1943. The alloy contains zinc, magnesium, chromium and copper as hardeners, along with smaller amounts of iron, silicon, manganese and titanium. After heat treatment, Al-7075 is much stronger than carbon steel. The common tempers are 7075-T6, T651, T7351, T73, T76, T7651,etc.

7075 T6 has the highest mechanical strength properties, but its fracture toughness is low and it is sensitive to stress corrosion. Its toughness decreases as the temperature decreases. Therefore, 7075t6 is not suitable for manufacturing low-temperature structural parts and workpieces.

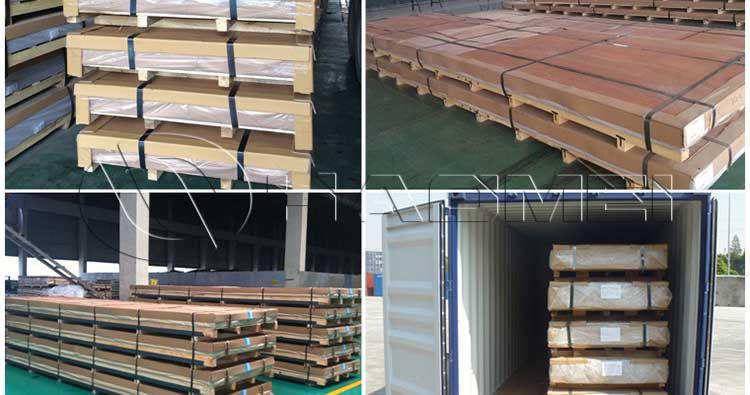

Haomei Aluminum’s 7075 aluminum plate is stress-relieved and will not deform or warp after processing. All ultra-large and ultra-thick 7075 aluminum plates have been ultrasonic tested to ensure there are no blisters or impurities.

The 2000 series aluminum alloy has excellent temperature resistance and is mainly used in aerospace high-temperature components. The excellent temperature resistance is mainly due to the complex chemical composition and phase composition of the 2000 series aluminum alloy, which can maintain good strength stability and process performance.

2024 aluminum alloy is commonly used in T3 and T4 states, which have high plasticity, fatigue life, fracture toughness and resistance to fatigue crack growth, but poor corrosion resistance. This alloy thick plate is mainly used in fuselages, wings, shear floors and webs, and other structural parts with high strength requirements.

2024 aluminum alloy has excellent strength and performs well under normal and low temperature conditions, making it suitable for applications requiring high strength. After T3 state heat treatment, the hardness of 2024 aluminum alloy is about HB120. 2024 t351 and 2024 t4 has higher hardness, reaching around HB140.

Original Source:https://www.aircraftaluminium.com/a/what-are-aluminum-alloys-for-aerospace-manufacturing.html

Tags: aircraft aluminum sheet ,

Contact Us