In today’s aerospace industry, when it comes to which material is used the most, there is no doubt that it is aluminum alloy. Compared with ordinary aluminum alloys, aluminum alloys used in aircraft have higher requirements for strength, hardness, toughness, fatigue resistance and plasticity.

7xxx series and 2xxx series high-strength and tough aluminum alloys have the largest usage, variety and specifications among all aviation aluminum alloys, and are the most representative aircraft aluminum alloys. The typical grades are 7075, 7475, 7050, 7085, 7055, 2024, 2524, 2424, 2A12,etc.

The 2000 series aluminum alloy has excellent temperature resistance and is mainly used in aerospace high-temperature components. The excellent temperature resistance is mainly due to the complex chemical composition and phase composition of the 2000 series aluminum alloy, which can maintain strength stability and process performance at high temperatures.

2024 aluminum alloy is a commonly used material in the current aircraft manufacturing process. It not only has high plasticity, but also has many advantages such as fatigue expansion resistance, heat resistance, and fracture toughness. What are al 2024 material properties?

2024-T351 alloy aluminum has high strength, good cutting performance, high strength, heat resistance, good spot welding, and significant heat treatment strengthening effect. Anodizing and painting methods are used or an aluminum layer is added to the surface to improve its corrosion resistance. It is mainly used for aircraft skeleton components, rivets, wing spars, truck hubs, propeller components, bulkheads and other structural parts as well as working parts within 150 ℃.

7075 aluminum alloy is a high-strength, heat-treatable deformed alloy developed by Alcoa in 1943. The alloy contains zinc, magnesium, chromium and copper as hardeners, along with smaller amounts of iron, silicon, manganese and titanium. It is commonly used in manufacturing aircraft structures. 7075t6 is its popular temper.

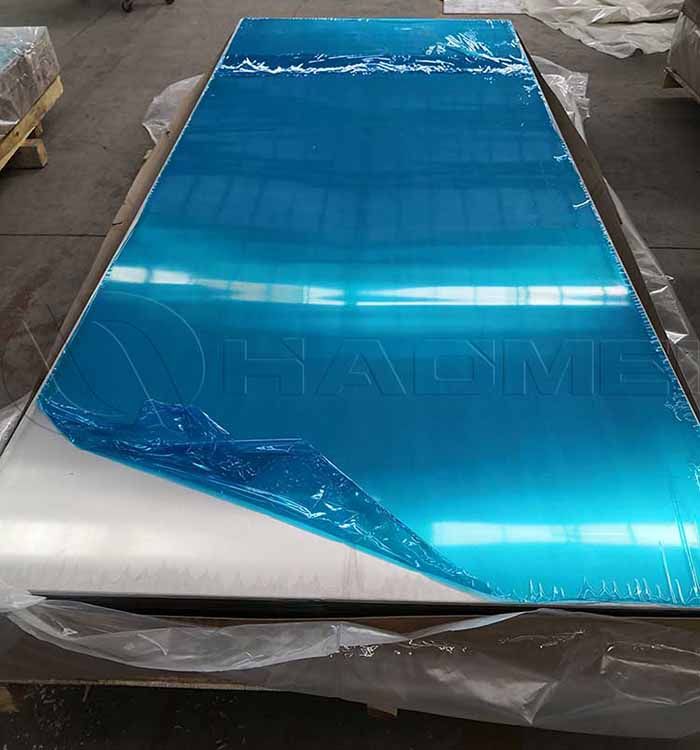

7075 aluminum sheet has good plasticity after solution treatment, and the heat treatment strengthening effect is particularly good. It is an ultra-high-strength deformed aluminum alloy widely used in the aviation industry, and has good mechanical properties and anodic reaction. 7075 ultra-thick aluminum plate meets the high requirements of the partition frames like good low-temperature strength , so 7075 aviation aluminum is suitable for partition frames.

Original Source:https://www.aircraftaluminium.com/a/what-are-aluminum-alloys-used-in-aerospace-industry.html

Tags: aircraft aluminum alloy ,

Contact Us