In today's aviation industry, if you want to say which material is used the most, there is no doubt that it must be aluminum alloy. There is a a comparison of the properties of typical aviation aluminum alloys 20424, 7075 and 6061.

2024 aluminum alloy belongs to Al-Cu-Mn aluminum alloy. How about Al 2024 properties? It is a kind of high-strength hard aluminum, which can be strengthened by heat treatment, and has medium plasticity in quenched and just-quenched state and good spot welding performance.

The alloy has good machinability after quenching and cold work hardening, and low machinability after annealing. The corrosion resistance is not high, so anodic oxidation treatment and painting methods are often used to improve its corrosion resistance.

It is mainly used to make various high-load parts and components (but not including stamping forgings), such as skeleton parts, skins, bulkheads, ribs, spars, rivets and other working parts below 150 °C on aircraft.

6061 aluminum alloy belongs to the Al-Mg-Si series aluminum alloy. It is a high-quality aluminum alloy produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2xxx series or 7xxx series, it has many characteristics of magnesium and silicon alloys.

It has excellent processing performance, excellent welding characteristics and electroplating properties, good corrosion resistance, high toughness, no deformation after processing, compact material without defects, easy polishing, easy coloring film, and excellent anodizing effect.

In the field of aerospace, it is mainly used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear pillars, as well as rocket forging rings, spacecraft wall panels, etc.

7075 aluminum alloy belongs to Al-Zn-Mg-Cu series aluminum alloy, which is a cold-treated forging alloy with high strength, which is better than mild steel. I has common corrosion resistance and good mechanical properties.

Zn is the main alloying element in 7075. Adding magnesium to the alloy containing 3%-7.5% zinc can form MgZn2 with significant strengthening effect, making the heat treatment effect of the alloy far better than that of Al-Zn binary alloy. Increasing the content of zinc and magnesium in the alloy will further increase the tensile strength, but its ability to resist stress corrosion and exfoliation corrosion will decrease accordingly. After heat treatment, it can achieve very high strength characteristics.

Matweb 7075 is generally added with a small amount of copper, chromium and other alloys. Its typical uses include aerospace, mold processing, mechanical equipment, tooling fixtures, especially for manufacturing aircraft structures and other high-stress structures that require high strength and strong corrosion resistance.

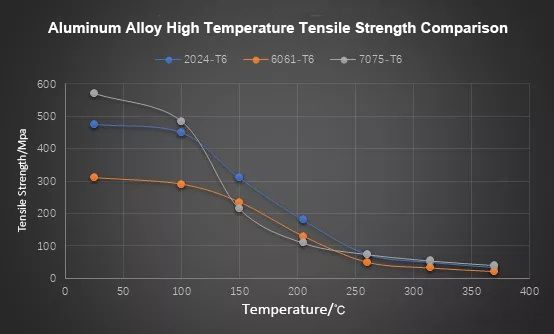

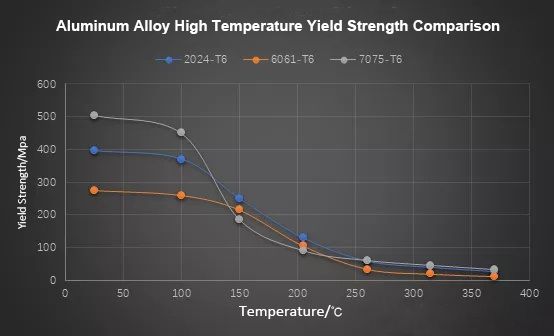

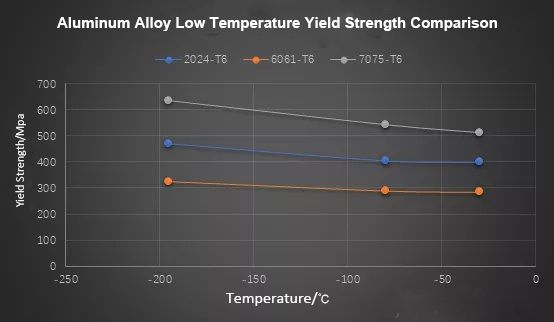

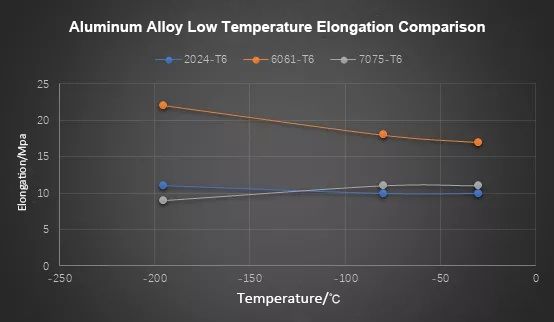

7075 aluminum alloy has the highest strength and 6061 aluminum alloy has the lowest strength.

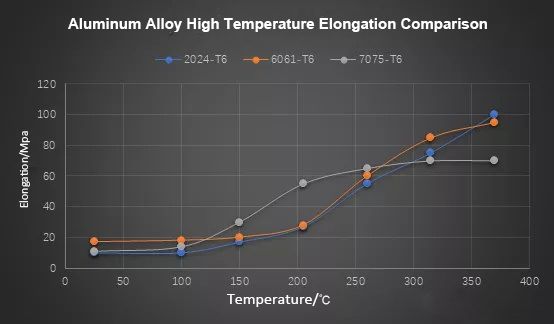

By comparing the yield strength, tensile strength, and elongation, it can be found that the mechanical properties of the material decrease significantly with the increase of temperature. At 150-200°C, the relationship between the advantages and disadvantages of the mechanical properties of different aluminum alloys has changed.

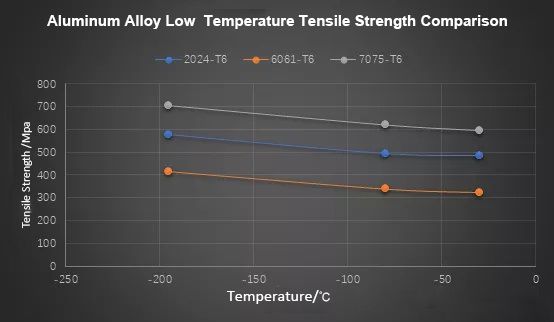

The mechanical properties of aluminum alloys at low temperatures are shown in the figure below. As the temperature decreases, the strength of the material increases.

Original Source:https://www.aircraftaluminium.com/a/aerospace-aluminum-2024-7075-6061-properties.html

Tags: aircraft aluminum sheet ,

Contact Us