Al-Cu-Mg aluminum alloys are typical age-strengthened alloys. The use of appropriate solution and aging treatments can make this series of aluminum alloys have higher strength and good heat resistance. Therefore, they are used as important structural materials and widely used in aviation industry. The main alloys are 2011, 2017, 2014 and AA2024 aluminum alloy.

2017 and 2024 alloys are duralumin. 2017 alloy can be strengthened under natural aging (T4) and 2024 is also of high strength, which are are used as aircraft components, various forged parts, vehicle components, etc.

AA2011 has trace amounts of lead and bismuth, and its strength is roughly the same as that of the 2017 alloy, but it has higher performance than 2017 alloys under natural aging.

Second only to aluminum alloy 2024 in terms of its popularity in aerospace engineering, 2014 aluminum alloy is a strong, tough metal suitable for arc and resistance welding. Due to the higher copper content, its strength is higher and the thermal strength is better, but it has low corrosion resistance, so it is often found in the internal structure or framework of aircraft rather than the shell.

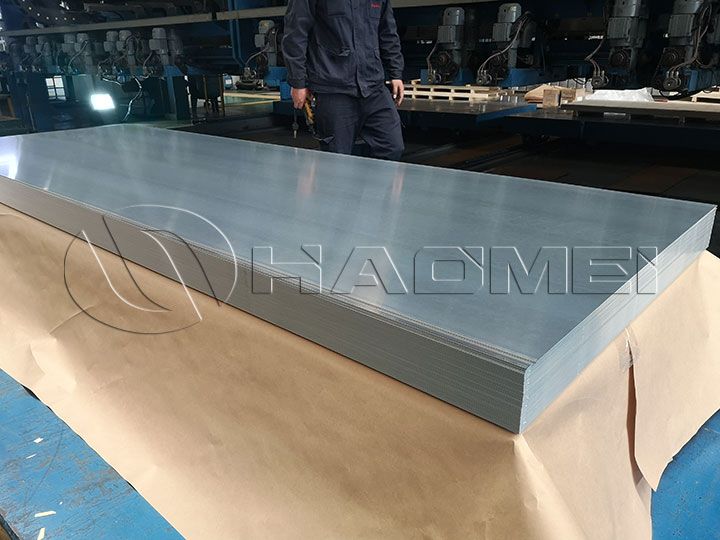

2014 aluminum sheet is with silicon, manganese, copper and magnesium as the main elements. It features high yield strength and good formability, which is widely used for the components with relatively high strength. Aluminium 2014 t6 is with relatively high strength while aluminum 2014 t4 is for parts requiring toughness.

2014 Aluminum sheet is used to manufacture parts that require high strength, high hardness and high load, such as wheels, truck frames and suspension assemblies, fuel tanks and structural parts of rocket boosters, etc. It can be also cladded with pure aluminum to improve its corrosion resistance.

High Temperature Tensile Properties Of 2014 Aluminum Alloy At Different Temperatures | ||||

Temper | Temperature(℃) | Tensile strength(Rm/MPa) | Plastic extension strength(Rp0.2/MPa) | Elongation A (%) |

T6 | 100 | 439 | 393 | 15 |

150 | 276 | 241 | 20 | |

204 | 110 | 90 | 38 | |

260 | 66 | 52 | 52 | |

315 | 45 | 34 | 65 | |

370 | 30 | 24 | 72 | |

Original Source:https://www.aircraftaluminium.com/a/what-are-properties-of-2014-aluminum-sheet.html

Tags: 2014 aluminum alloy ,

Contact Us